Industrial Grade Asiaalloy 8K Finish Steel Plates for Various Applications

| Model NO. | 1100103 |

| Surface Treatment | Grinding |

| Application | Mold & Dies, Ship Plate, Boiler Plate, Container Plate, Flange Plate |

| Stock | Stock |

| Surface | 2b, Ba, 4K, 8K, Hl and PVC Cover |

| Specification | 0.5 0.6 0.8 1.0 1.2 1.5 2.0 3.0 4.0 5.0mm |

| Origin | China |

| Certification | ISO |

| Technique | Cold Rolled |

| Special Use | Cutting Tools, Measuring Tools, Cutters in Common Steel, High-strength Steel Plate, Wear Resistant Steel, Silicon Steel |

| Thickness | 0.3mm-10.0mm |

| Transport Package | Woven Bags, Plastic Bags, Cap Ends, Plywood Cases |

| Trademark | Asiaalloy |

| HS Code | 7306900090 |

| Production Capacity | 15000 Ton/Year Product Description |

Description

Grade:Meticulously manufactured in the renowned 300 Series and 400 Series, including Austenitic and Ferritic grades, ensuring versatility and reliability in every sheet.

Standard:Compliant with global standards such as ASTM, AISI, DIN, EN, GB, and JIS, our products promise consistency and excellence across various industrial demands.

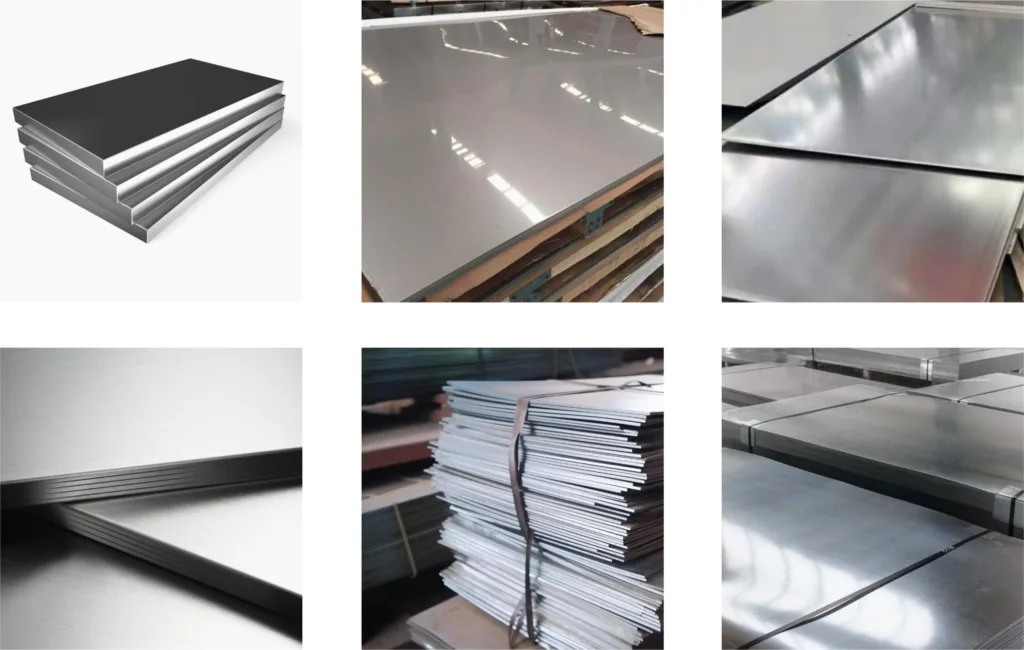

Length:Available in lengths of 2438mm, 3000mm, and 6000mm, with the possibility of tailor-made dimensions to suit your unique project requirements.

Width:Widths offered include 1000mm, 1219mm, 1500mm, and 2000mm, providing flexibility to match your specific industrial needs.

Thickness:Ranging from 0.3mm to 10.0mm, our metal plates are designed to meet diverse thickness specifications, ensuring optimal performance for every application.

Place of Origin:Proudly originating from Jiangsu, China (Mainland), a hub of industrial manufacturing excellence.

Model Number:Our robust selection includes models 201, 304, 304L, 310S, 316, 316L, 321, and 430, catering to various industrial applications.

Type:Available in both hot rolled and cold rolled types, these plates offer adaptability and strength for a multitude of uses.

Application:Perfectly suited for architecture, construction, building projects, and kitchenware, our metal plates are the epitome of strength and aesthetic appeal.

Certification:Certified by BV, IBR, ISO, ROHS, and SGS, our products guarantee quality and trustworthiness, meeting international safety and efficiency standards.

Surface:Featuring a variety of finishes such as 2B, BA, 4K, 8K, HL, with optional protective PVC cover to ensure longevity and aesthetic integrity.

Note:We are committed to flexibility and can accommodate additional materials as needed, tailoring solutions to your project’s specific requirements.

Detailed Information: Immerse yourself in the world of unparalleled excellence with our Durable Cold Rolled Stainless Steel Sheet, boasting a distinctive 2b Ba Surface. Discover the superior quality and remarkable performance that make our stainless steel sheet a cut above the rest.

| Typical chemical composition | ||||

| % | 304 | 304L | 310s | 321 |

| C | 0-0.07 | 0-0.03 | 0.8 | 0.08 |

| Mn | 0-2.0 | 0-2.0 | 2.00 | 2.00 |

| Si | 0-1 | 0-1 | 1.00 | 1.00 |

| P | 0-0.05 | 0-0.05 | 0.035 | 0.035 |

| S | 0-0.02 | 0-0.02 | 0.030 | 0.03 |

| Cr | 17.5-19.5 | 17.5-19.5 | 24.0-26.0 | 17.0-19.0 |

| Ni | 8-10.5 | 8-10.5 | 19.0-22.0 | 9.0-12.0 |

| Mo | ||||

| TI | 5×C% | |||

| Fe | Balance | Balance | ||

| Item | Material | Specification |

| 316Series Stainlee Steel Sheet/Plate | 316L/2B 316L/NO.1 316Ti 317L | Thickness:0.4-40 mm Width:≥1000 mm Length:≥6000 mm |

| 304 Series Stainlee Steel Sheet/Plate | 304/2B 304/NO.1 304L/NO.1 | Thickness:0.4-40 mm Width:≥1000 mm Length:≥6000 mm |

| 321 Series Stainlee Steel Sheet/Plate | 321/2B 321/NO.1 | Thickness:0.4-60 mm Width:≥1000 mm Length:≥6000 mm |

Surface Finishing: Elevate your stainless steel applications with our immaculate and exquisite 2b Ba surface finishing, designed to deliver a sophisticated and elegant appearance. Our advanced surface finishing process not only enhances visual appeal but also significantly boosts durability, establishing a new benchmark in the industry.

| Surface | Definition | Application |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size | Building Construction. |

| BA (No.6) | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| Mirror (No.8) | Shinning like a mirror | Building construction |

Detailed Photos

FAQ

What is the main difference between 304 and 430 stainless steel?

The primary distinction lies in their chemical composition and intrinsic properties. 304 stainless steel incorporates approximately 18% chromium and 8% nickel, endowing it with exceptional corrosion resistance and heat tolerance, which makes it ideal for applications in the food and medical industries. On the other hand, 430 stainless steel contains about 16-18% chromium and lacks nickel, offering superior processing properties and enhanced thermal conductivity.

Is the product magnetic?

No, 304 stainless steel is non-magnetic, ensuring it is suitable for various non-magnetic applications.

What should I be careful about when handling the product?

Since the material is metal, handle with care as edges and corners can be sharp, potentially causing injuries. Additionally, the surface is protected by a transparent film that should be removed prior to use to achieve optimal performance.