Hastelloy C276 C22 C4 B2 B3 G30 G35 C2000 Nickel Alloy Steel Plate

| Model NO. | Hastelloy c276 c22 c4 b2 b3 g30 g35 c2000 |

| Composition | Hastelloy Alloy |

| Technique | Cold Drawn |

| Shape | Plate |

| Surface Treatment | Polished |

| Special Use | High-strength Steel Plate, Wear Resistant Steel, Silicon Steel, Cold Heading Steel, Free Cutting Steel, Mold Steel |

| Application | Power Plant Desulfurization and Denitration, Therm |

| MOQ | 20kg |

| Trade Terms | EXW, Fob, CIF, CFR |

| Stock | Stock Available |

| Transport Package | Marine Packaging of Metal |

| Specification | Ultra-thin 0.005~0.3mm range |

| Trademark | Alloy |

| Origin | China |

| HS Code | 7226920000 |

| Production Capacity | 5000ton/Month |

Description

Hastelloy Plate is a nickel-based superalloy renowned for its excellent corrosion resistance and high-temperature strength. Its primary components typically include nickel (Ni), molybdenum (Mo), chromium (Cr), iron (Fe), and small amounts of cobalt (Co) and tungsten (W). This alloy is mainly used in extremely harsh corrosive environments and high-temperature applications.

Common Grades of Hastelloy Plate

Hastelloy C-22

- Offers excellent all-around performance and resistance to both oxidizing and reducing environments.

- Ideal for equipment such as heat exchangers, reactors, and scrubbers in the chemical industry.

Hastelloy C-276

- Known as the “all-purpose alloy” in the chemical industry, it provides outstanding resistance to strong acids, bases, and chloride environments.

- Widely used in pulp, chemical, and pharmaceutical industries.

Hastelloy B-2/B-3

- Provides exceptional resistance to reducing agents like hydrochloric acid ,primarily used in acidic solutions.

Hastelloy G-30/G-35

- Designed for wet process phosphoric acid environments and hydrometallurgy, with superior pitting resistance.

Hastelloy X

- Primarily used in high-temperature applications, such as gas turbines and industrial furnaces

| Property | Hastelloy Alloy Sheets |

| Material Composition | Similar to Hastelloy strips, these sheets are made of nickel-based alloys with high concentrations of molybdenum, chromium, and sometimes iron and tungsten for enhanced resistance to high-temperature corrosion. |

| Thickness | Generally thicker than strips, ranging from 1 mm to several centimeters, suitable for structural and high-stress applications. |

| Applications | Commonly used in the manufacturing of components like reactor vessels, valves, and piping systems, as well as aerospace, power generation, and chemical processing equipment. |

| Mechanical Properties | Excellent mechanical strength and toughness, making them ideal for structural and high-stress applications. They also offer good formability and weldability. |

| Corrosion Resistance | Similarly, Hastelloy sheets are highly resistant to pitting, crevice corrosion, and stress corrosion cracking, making them ideal for aggressive chemical and industrial environments. |

| Thermal Resistance | Similar to strips, sheets retain their strength and resist oxidation in high-temperature environments, even in applications exceeding 1000°C (1832°F). |

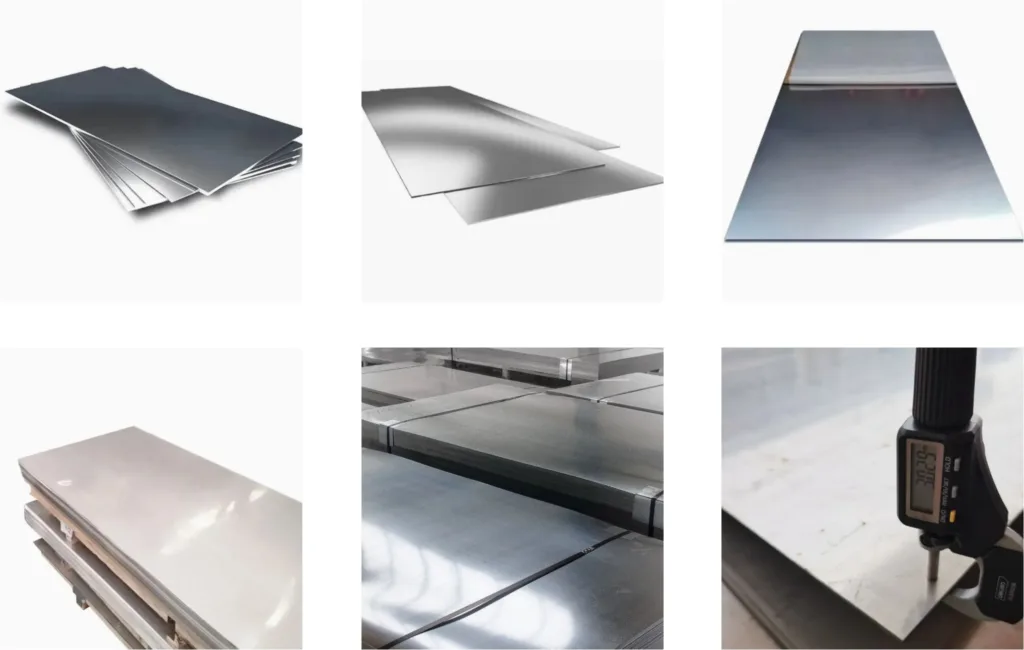

| Forming & Fabrication | Hastelloy sheets are typically hot-rolled or cold-rolled and may be subjected to heat treatment (annealing) for improved strength and ductility. They can be welded, bent, or machined for complex shapes. |

| Heat Treatment | Heat treatments such as solution annealing or stress relieving are commonly applied to improve the performance of Hastelloy sheets in high-temperature environments. |

| Welding & Joining | Hastelloy sheets are highly weldable, and various welding techniques (e.g., TIG, MIG, electron beam welding) can be used. However, welding requires control of heat input to avoid compromising corrosion resistance. |

| Examples of Alloys | Hastelloy C-276, Hastelloy C-22, Hastelloy B-3, Hastelloy X |

| Cost | Similar to strips, Hastelloy sheets are more expensive than standard steel due to the high alloy content and complex processing. |

| Common Standards | ASTM B575, ASTM B626, ASTM B469, ASME SB-575. |

Detailed Photos

FAQ

Are you a factory or a trading company?

We are a dedicated factory specializing in the manufacturing of seamless stainless steel pipes. Additionally, we offer welded stainless steel pipes and pipe fittings to meet your comprehensive needs. Our in-depth market knowledge ensures that we deliver only the highest quality products, each meticulously inspected before shipment.

Do you have any certificates?

We proudly hold numerous prestigious domestic and international certifications, including the EU ISO9001 Quality Management System Certification, TUV Welding Certification, and the China Pressure Pipe Manufacturing License (TS).We are also exclusively authorized by the American Hastelloy Company in China for the collaboration, development, and production of Hastelloy long products.

What is your delivery time?

Delivery time primarily depends on your order volume. Typically, we deliver within approximately one month for a standard 40FT container. For in-stock items, shipping can be expedited to just 5 days.

What are your payment terms?

Our standard payment terms are a 30% deposit with the remaining balance against the bill of lading. We also accept L/C. Shipping terms include EXW, FOB, CFR, and CIF, tailored to your preference.

How can you guarantee the quality of my goods?

We ensure all materials undergo 100% PMI testing and precise measurement before shipping. We welcome third-party inspections and provide the EN10204.3.1B Mill Test Certificate for all materials.

How do you establish long-term and positive business relationships?

1. We maintain superior quality and competitive pricing to maximize our customers’ benefits.

2. We respect every customer, conducting business with sincerity and maintaining high service standards both before and after every transaction.