When Metal Meets Extreme Environments

In the history of human industrial civilization, every breakthrough in metallic materials has driven leaps in technological advancement. When traditional stainless steel “fails” in harsh environments—strong acids, high temperatures, or salt spray—a material known as the “ultimate line of defense” in industrial applications, Hastelloy C22, emerges. It serves not only as the “armor” for chemical equipment and the “heart” of military systems but also quietly permeates daily life in fields like healthcare and environmental protection. Today, let’s unveil the mystery of this “super alloy” and explore how it transitioned from laboratories to every corner of human civilization.

01 The History of Hastelloy C22: A Technological Revolution Against Corrosion

1.1 The Pain of Corrosion: A Roadblock to Industrial Progress

By the mid-20th century, with the explosive growth of industries such as petrochemicals and nuclear energy, equipment degradation under high-temperature, high-pressure, and highly corrosive conditions became increasingly severe. Traditional stainless steel corroded rapidly in concentrated hydrochloric acid or chlorine-containing solutions, even leading to leakage incidents. The quest for a “rust-proof” metallic material became the ultimate goal for global materials scientists.

1.2 The Birth of Hastelloy: A Laboratory Miracle

In the 1960s, scientists at **Haynes International** in the U.S. pioneered the development of a nickel-based alloy family. **Hastelloy C22 (UNS N06022)**, as the third-generation product, debuted in the 1980s. By optimizing the ratios of chromium, molybdenum, tungsten, and other elements, it achieved “absolute defense” against extreme corrosive environments, earning the title of “a milestone in corrosion-resistant alloys.”

1.3 Standards and Certifications: From Industry Norms to Global Recognition

Thanks to its exceptional performance, Hastelloy C22 quickly became part of international standards such as ASTM and ASME, solidifying its status as the “designated material” in industries like chemical processing and nuclear power. Its designation, N06022, became synonymous with “reliability” in the minds of engineers.

02 The Properties of Hastelloy C22: Decoding the “King of Metals”

2.1 Chemical Composition: The Golden Formula of Elemental Ratios

– Nickel (Ni) (56%): Provides a stable crystalline structure, resisting oxidation and thermal fatigue.

– Chromium (Cr) (22%): Forms a dense oxide film to combat acidic media corrosion.

– Molybdenum (Mo) (13%) + Tungsten (W) (3%): A dual force against chlorides and localized corrosion.

– Iron (Fe) (3%) + Cobalt (Co) (2.5%): Enhances high-temperature strength for extreme thermal environments.

2.2 Performance Metrics: Challenging Physical Limits

– Corrosion Resistance: Resists boiling concentrated hydrochloric acid, sulfuric acid, seawater, and even mixed acids containing F⁻and Cl⁻.

– Thermal Stability: Maintains strength across temperatures from -196°C to 600°C, with transient tolerance up to 1200°C under oxidizing conditions.

– Mechanical Properties: Tensile strength ≥690 MPa, hardness HRC 25, balancing toughness and wear resistance.

2.3 Comparative Testing: Data Speaks Louder

In ASTM G28 standard tests, Hastelloy C22 exhibited a corrosion rate of 0.1 mm/year in a 70% sulfuric acid + 5% CuSO₄ solution, while 316L stainless steel corroded at 25 mm/year—a staggering 250-fold difference!

03 Daily Life: The Invisible “Metal Guardian”

3.1 Chemical Industry: The Unsung Hero of Production Safety

– Reactors & Piping: Withstands 160°C acetic acid + bromide corrosion in PTA (purified terephthalic acid) production.

– Flue Gas Desulfurization Systems: Acts as the “last line of defense” in coal-fired power plants against Cl⁻ and SO₂-laden acidic gases.

3.2 Environmental Protection: A Silent Contributor to Sustainability

– Wastewater Treatment Equipment: Lasts 5 times longer than titanium alloys in electroplating acid-waste solutions.

– Nuclear Waste Containers: Used at the U.S. Hanford Nuclear Site to encapsulate high-level radioactive waste, ensuring safety for millennia.

3.3 Healthcare: A Key Material in Life Sciences

– Artificial Joint Coatings: Leverages biocompatibility to reduce metal ion release and rejection.

– MRI Coils: Ultra-high-purity C22 wiring enables precise magnetic field control.

04 Military & Advanced Manufacturing: The Backbone of National Power

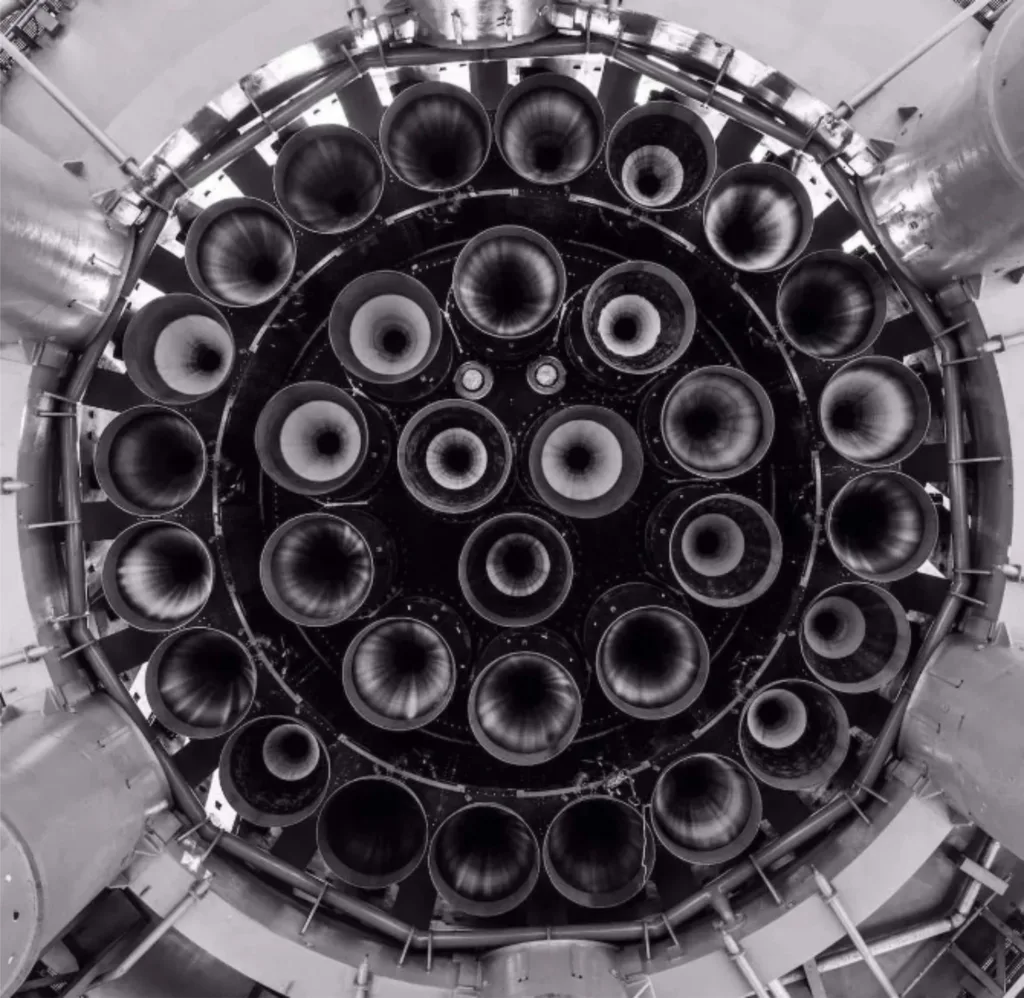

4.1 Aerospace: The “High-Temperature Armor” Breaking Limits

– Rocket Engine Combustion Chambers: SpaceX’s Raptor engines use C22 liners to endure 3300°C oxygen-rich exhaust.

– Carrier-Based Aircraft Hydraulic Lines: Ensures 20,000 hours of maintenance-free operation in marine salt-spray environments.

4.2 Marine Engineering: Core Support for Deep-Sea Ambitions

– Deep-Sea Submersible Pressure Hulls: Welding material for the “Fendouzhe” crewed cabin, resisting 10,000-meter water pressure.

– Aircraft Carrier Steam Catapult Systems: C22 pipelines achieve 100,000 launches with zero failures under high-temperature steam.

4.3 Energy Security: The Key to the Future

– Fourth-Gen Nuclear Reactors: China’s prototype fast reactor employs C22 in sodium-cooled loops to eliminate liquid metal corrosion.

– Shale Gas Supercritical CO₂ Fracturing: C22 downhole tools break traditional steel component lifespan limitations.

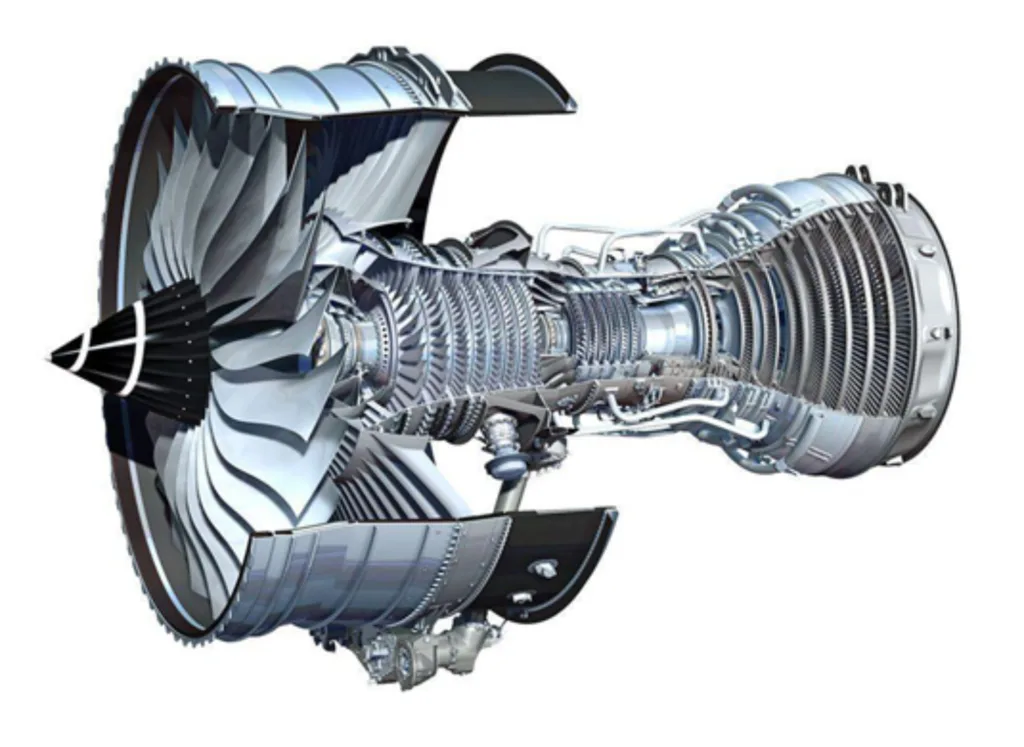

05 Future Trends: Infinite Possibilities in the New Material Era

5.1 Additive Manufacturing: Revolutionizing Traditional Processing

– 3D-Printed Aerospace Components: GE has achieved mold-free C22 turbine blade production, reducing weight by 30%.

– Microreactor Customization: Laser cladding enables micron-scale chemical reaction chips.

5.2 Green Metallurgy: The Path to Sustainability

– Waste Recycling: Haynes International’s C22 scrap recovery process achieves 99.5% nickel recovery.

– Hydrogen Storage Breakthroughs: C22 tanks withstand 70 MPa hydrogen pressure with zero embrittlement risks.

5.3 Smart Materials: Cross-Disciplinary Innovation

– Self-Healing Coatings: C22 composites embedded with microcapsules release repair agents at crack sites.

– Nuclear Sensors: C22 substrates integrated with fiber-optic networks enable real-time stress monitoring.

Materials Shape the Future

From laboratory test tubes to components on Mars rovers, the story of Hastelloy C22 proves a universal truth: **Every leap in human civilization begins with a profound understanding and innovation in materials**. In an era of carbon neutrality, deep-space exploration, and smart healthcare, this “King of Metals” will continue to forge legends. Perhaps one day, when our descendants unscrew a C22 bolt on a Martian base, they will marvel at the wisdom and vision of today’s materials scientists.