Among the common stainless steel products in hospitals, medical cabinets can be specifically classified into various types such as instrument cabinets, medicine cabinets, injection cabinets, narcotic cabinets, and traditional Chinese medicine cabinets. These common stainless steel medical cabinets are a basic configuration in modern hospitals. For example, stainless steel instrument cabinets are typically used in operating rooms to store various surgical instruments, medicines, and anesthetics. Compared to traditional wooden cabinets and iron cabinets, medical stainless steel medicine cabinets/instrument cabinets are usually made from cold-rolled stainless steel plates through multiple processes such as laser cutting, sheet metal bending, welding, and assembly. They are characterized by being waterproof, moisture-proof, rust-resistant, corrosion-resistant, and durable.

465 Stainless Steel (S46500)

465 stainless steel (S46500) is a martensitic precipitation-hardening stainless steel with extremely high strength, excellent toughness, and corrosion resistance. This steel was first used in the aerospace industry in 1997 and later widely applied in aircraft structural components such as engine fittings, flap tracks, actuators, landing gear parts, and similar components. Due to its unique and excellent mechanical properties and corrosion resistance, it has gradually been adopted in the manufacturing of medical devices and has achieved widespread and successful applications.

465 stainless steel is extensively used in the medical device industry because it combines outstanding strength and toughness, allowing instruments to withstand high torque during surgical procedures. The unique properties of Custom 465 stainless steel make it possible to design smaller and more compact instruments for minimally invasive surgeries.

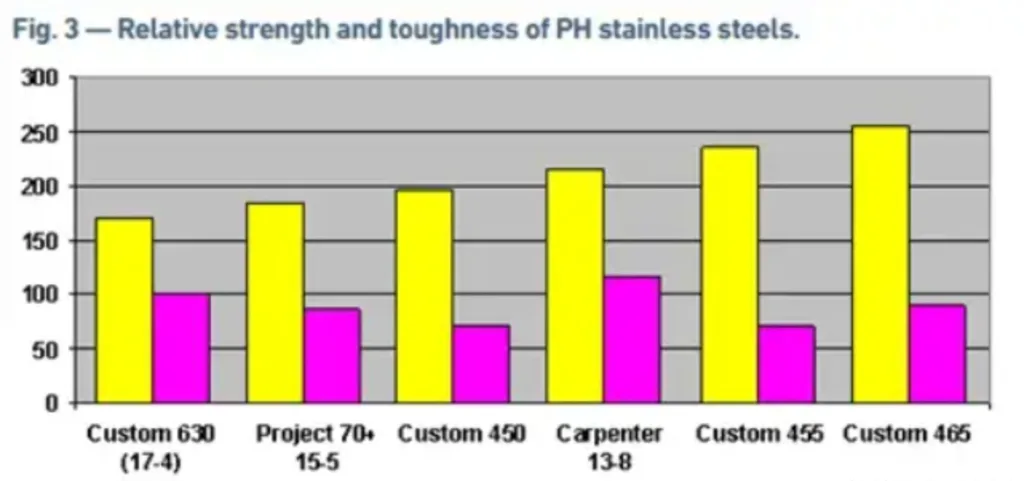

When manufacturing surgical tools, the alloy’s excellent fracture and impact toughness are crucial. Under similar material strength conditions, 465 stainless steel has more than twice the impact toughness of other commonly used medical precipitation-hardening stainless steels like 455 and 17-4 alloys. In its peak-aged (H900) state, it can achieve a strength of 1820 MPa while maintaining excellent notch strength and fracture toughness. It retains high strength even after long-term thermal exposure and has corrosion resistance similar to AISI 304 steel. The dimensional changes caused by heat treatment are minimal, and it can be cold-worked in both solution-treated and various machined states.

465 stainless steel is mainly used to manufacture cutting instruments such as reamers, scissors, files, and knives, as well as non-cutting instruments like clamps, punches, impactor guides, impact plates, screwdrivers, and hex screwdrivers. The chemical composition (%) is based on ASTM A564 2004 and AMS 5936D standards. AMS 5936 specifies the requirements for corrosion-resistant steel bars, wires, and forgings (12Cr-11Ni-1.7Ti-1Mo) produced by vacuum induction melting followed by vacuum arc remelting, solution-treated, and age-hardenable. ASTM-F899 provides the standard specification for wrought stainless steel for surgical instruments, and ASTM-A564 outlines the technical specifications for hot-rolled and cold-finished age-hardening stainless steel bars and shapes.

Mechanical performance tests have proven that 465 stainless steel has superior tensile strength among age-hardening stainless steels. Similar grades include UNS S46500 and Alloy 465. Custom 465 stainless steel, when aged at 900°F (482°C), can provide a maximum achievable tensile strength of nearly 300 ksi (2070 MPa) for parts with diameters less than 0.75 in. (20 mm). This capability is highly beneficial for manufacturing surgical and dental instruments and needle wires for the medical industry. While more traditional ferritic and martensitic stainless steels were sufficient for making surgical instruments for a long time, this situation has changed. New surgical techniques require the design of more advanced surgical instruments that do not break, twist, or fail during procedures. The materials used for these instruments must be robust and durable. The high strength and toughness of 465 stainless steel allow instruments to withstand higher operational torque loads during surgery. These properties facilitate the design and application of longer, smaller cross-sectional surgical instruments typically needed in minimally invasive surgeries.

When the alloy is used for surgical tools, excellent fracture and impact toughness are also critical. At similar strength levels, 465 stainless steel has more than twice the impact resistance of 455 stainless steel or 17Cr-4Ni (630) stainless steel, both of which are alternative precipitation-hardening stainless steels used in the medical industry.

Instruments made from 465 stainless steel are autoclavable and exhibit good oxidation resistance in steam environments. The alloy has also been found to resist cleaning and disinfecting solutions as well as bodily fluids. 465 stainless steel is included in ASTM F899, the standard specification for wrought stainless steel for surgical instruments, indicating that it is a suitable choice for surgical instrument applications.

Although not specifically designed for wear resistance and edge retention, 465 stainless steel has been used in instruments such as scrapers and knives, outperforming 455 and 17-4 (630 stainless steel). In addition to its use in surgical tools, 465 stainless steel, due to its excellent combination of high strength, ductility, and corrosion resistance, is also suitable for producing suture needles. The primary uses of 465 stainless steel include aerospace structural components, medical devices, and hand tools. Instruments made from 465 stainless steel can be sterilized at high temperatures and are oxidation-resistant in steam environments. The alloy is resistant to cleaning and disinfecting solutions and is used in cutting instruments such as reamers, scissors, files, and knives, as well as non-cutting instruments like clamps, punches, impactor guides, impact plates, screwdrivers, and hex screwdrivers. Additionally, 465 stainless steel has applications in consumer, defense, energy, and industrial fields.

Which is Better for Fracture Surgery: Titanium Alloy or Stainless Steel Plates and Screws?

Currently, only a small portion of the plates and screws used in fracture surgery are made of stainless steel, with the majority being titanium alloy. Titanium alloy is an inert metal with good biocompatibility and is less prone to fracture. It also has a lower infection rate compared to stainless steel. However, this does not mean that stainless steel does not have its own advantages.

Stainless Steel Alloy

Stainless steel alloys have been used in orthopedic surgery for over 100 years and are still in use today. Type 316L stainless steel is commonly used for bone tissue healing. Type 316L medical stainless steel was popular from the 1970s to the 1990s because it is the most corrosion-resistant when in direct contact with biological fluids. It is typically used to manufacture surgical plates and screws. Its advantages include:

1. A higher elastic modulus, meaning the material has a stronger resistance to elastic deformation and greater rigidity, making it harder than bone.

2. The torsional characteristics of stainless steel screws differ from those of titanium screws, making them easier to manipulate and alerting surgeons not to overtighten them.

3. It is cheaper than titanium alloy.

Titanium Alloy

Titanium is much lighter than stainless steel. The advantages of this material include an elastic modulus similar to that of bone, better elasticity and toughness, superior biocompatibility, and greater corrosion resistance. It also does not tarnish or cause allergic reactions. Compared to stainless steel, titanium has a lower infection rate. Some studies suggest that titanium alloy forms more callus during fracture healing and has fewer cases of nonunion compared to stainless steel. This is because titanium alloy plates allow for sufficient micromotion at the fracture site, which is beneficial for healing. However, titanium alloy also has its drawbacks:

1. It is expensive.

2. It is easily contaminated when exposed to hydrogen, nitrogen, and oxygen, which may affect its use.

3. Stainless steel may have better bending resistance than titanium.

Comparison Between the Two

Compared to stainless steel, titanium alloy is lighter but less prone to failure or fracture. Although titanium alloy has lower rigidity, it is generally stronger than stainless steel. Titanium alloy is less likely to cause immune reactions and has better corrosion resistance. Unlike stainless steel, titanium alloy can undergo MRI scans. Overall, titanium alloy outperforms stainless steel, and it is currently the mainstream choice. Titanium is flexible and can bend without breaking. It also stimulates bone growth around it, allowing the bone to fuse with the implant, resulting in a very secure fixation. For example, in hip replacements, titanium alloy is used for the femoral stem, and many patients still have their artificial joints in place over twenty years later, making it more suitable for younger patients.

Additionally, in studies on the fixation of distal femur and tibia fractures, titanium implants have lower failure and complication rates compared to stainless steel. When using intramedullary nails to treat tibial shaft fractures, titanium nails have a lower breakage rate than stainless steel. However, for areas such as the clavicle, distal radius, ankle, and foot, there is no definitive conclusion on the differences between the two materials.

Which One to Choose?

Titanium alloy offers better performance, while stainless steel is more cost-effective. If it is decided before surgery that the plate will be removed within a year or two, stainless steel plates or screws may be considered due to their lower cost. If the plate is not intended to be removed later, such as in spinal surgery, titanium alloy is recommended due to its excellent biocompatibility, resistance to corrosion over time, and good fit. Additionally, doctors will consider the specific fracture site when deciding which material to use.