Why Choose 1.4529 Stainless Steel?

In the industrial and chemical sectors, material selection directly impacts the lifespan, safety, and cost-effectiveness of equipment. 1.4529 stainless steel (UNS N08926), as a super austenitic stainless steel, is the ideal material for harsh environments due to its “exceptional corrosion resistance,” “high strength,” and “thermal stability.” This article will delve into the chemical composition, physical properties, application scenarios, and market advantages of 1.4529, providing you with a comprehensive understanding of its core competitiveness.

Part 1: Basic Properties of 1.4529 Stainless Steel

Material Classification and Standards

International Designation: UNS N08926, W.Nr.1.4529, EN 1.4529

Corresponding Standards: ASTM B688, ASTM B625, DIN 17744

Material Type: Austenitic-ferritic duplex stainless steel (super austenitic)

Chemical Composition Analysis (Key Alloying Elements)

The chemical composition of 1.4529 is based on high chromium, nickel, and molybdenum, with the addition of nitrogen and copper. The specific percentages are as follows:

Chromium (Cr) 19.0-21.0: Oxidation and pitting resistance

Nickel (Ni) 24.0-26.0: Enhances austenite stability and acid resistance

Molybdenum (Mo) 6.0-7.0: Resistance to chloride corrosion (suitable for seawater environments)

Nitrogen (N) 0.15-0.25: Improves strength and resistance to crevice corrosion

Copper (Cu) 0.5-1.5: Improves resistance to sulfuric acid environments

Manganese (Mn) ≤2.0: Deoxidation and processing optimization

Note: The low carbon content (C ≤ 0.02%) effectively avoids the risk of intergranular corrosion.

Part 2: Core Performance Advantages

Corrosion Resistance

Chloride environments: Pitting resistance equivalent number (PREN) ≥45, far superior to 316L (PREN ≈26), making it ideal for desalination, offshore platforms, etc.

Acidic media: Excellent performance in sulfuric acid, phosphoric acid, and acetic acid, with copper design ensuring resistance to up to 50% sulfuric acid concentrations.

High-temperature corrosion: Can withstand high concentrations of chloride solutions below 200°C for extended periods.

Mechanical Properties

Ultimate tensile strength (Rm): 650-850 MPa

Yield strength (Rp0.2): 300-400 MPa

Elongation (A5) ≥35%

Hardness (HBW): ≤220 (solid solution state)

Comparison Advantage: Compared to 316L stainless steel, 1.4529 exhibits approximately 30% higher strength while maintaining good formability.

Physical Properties

Density: 8.1 g/cm³

Thermal conductivity (20°C): 12 W/(m·K)

Electrical resistivity: 0.85 μΩ·m

Magnetic properties: Non-magnetic (austenite-dominant structure)

Part 3: Typical Application Areas

Marine Engineering

Desalination equipment (evaporators, piping systems)

Ship propeller shafts, pump and valve components

Subsea cable protection sheaths

Chemical and Petrochemical

Sulfuric acid recovery units

Flue gas desulfurization (FGD) systems

Acid gas transportation pipelines

Environmental and Energy

Nuclear power plant cooling water systems

Waste incineration plant flue gas treatment equipment

Geothermal power plant heat exchangers

Specialized Industries

High-purity medium containers in the pharmaceutical industry

Pulp bleaching equipment

Acid cleaning equipment in food processing

Part 4: Processing and Welding Guidelines

Hot Processing

Forging temperature: 1150-900°C (avoid below 850°C)

Annealing treatment: 1100-1170°C water quenching for optimal corrosion resistance

Cold Processing Recommendations

High-powered equipment is required due to the material’s high strength.

Post-processing solid solution treatment is recommended to relieve stress.

Welding Technology

Suitable methods: TIG, MIG, plasma welding

Recommended filler materials: Molybdenum- and nitrogen-containing welding wire (e.g., Sanicro 65)

Key control: Interlayer temperature ≤150°C to avoid carbide precipitation

Part 5: Market Competitiveness Analysis

Comparison with Similar Materials

Material: 316L

Chloride ion corrosion resistance: ★★☆☆☆

Cost index: 1.0

Maximum applicable temperature: 400°C

Material: 254SMO

Chloride ion corrosion resistance: ★★★★☆

Cost index: 2.3

Maximum applicable temperature: 450°C

Material: 1.4529

Chloride ion corrosion resistance: ★★★★★

Cost index: 2.0

Maximum applicable temperature: 500°C

Cost-Effectiveness Analysis

Although the initial purchase cost is higher than 316L, the service life in high-corrosion environments can be extended by 3 to 5 times, reducing equipment downtime and maintenance frequency, resulting in an overall total cost of ownership (TCO) reduction of more than 40%.

Global Supply Chain Status

Major producers: Sweden’s Sandvik, Germany’s ThyssenKrupp, Japan’s Metallurgical Industries

Chinese production capacity: Taiyuan Iron & Steel, Baoshan Iron & Steel are capable of mass production, shortening delivery times to 4-6 weeks.

Part 6: FAQ

Can 1.4529 replace titanium alloy?

In environments with ≤80°C hydrochloric acid and seawater systems, 1.4529 can replace Gr.2 titanium alloy, reducing costs by over 50%.

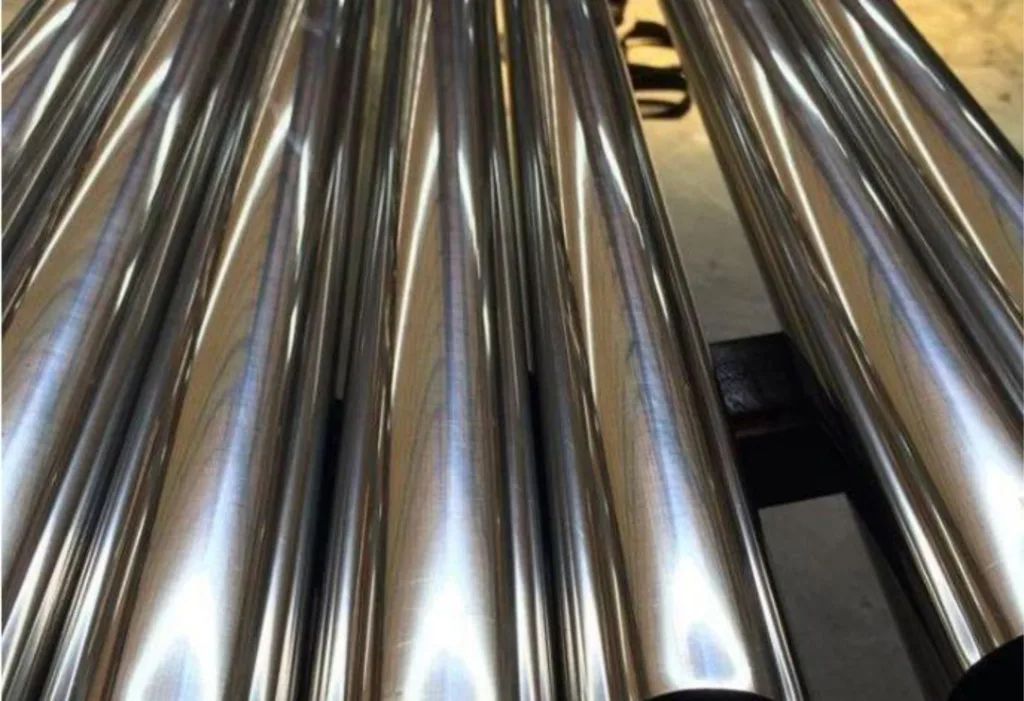

What are the available inventory specifications?

Commonly supplied in plate (0.5-50mm), pipe (OD6-630mm), and bar (Φ10-300mm). Custom heat treatment states are available.

How to identify authenticity?

It is recommended to use spectroscopic analysis and intergranular corrosion testing (ASTM A262 Practice E) to ensure the composition and corrosion resistance meet standards.

Future Prospects of 1.4529 Stainless Steel

With the tightening of global environmental regulations and the growing demand for industrial equipment upgrades, the applications of 1.4529 in emerging fields such as renewable energy and deep-sea development continue to expand. Choosing reliable suppliers and developing scientific processing plans can maximize the performance advantages of this material. For material samples or technical proposals, please contact our engineering team for customized material selection advice.